Dust in tissue converting is far more than a housekeeping issue — it directly affects product quality, machine uptime, and operator health. In regions such as the Middle East, where tissue production and consumption are expanding rapidly, dust management has become a decisive factor for operational performance and competitiveness.

The global tissue industry, long established and deeply rooted in manufacturing tradition, is steadily transforming as it responds, like many other industries, to growing demands for higher efficiency, process reliability, and product quality—alongside increasing environmental and sustainability expectations that are reshaping production standards worldwide.

At the same time, demand for ultra-soft, lightweight, and sustainable tissue products continues to rise. Yet these very product features make manufacturing lines more prone to dust generation. During converting, fine fibers, fluff, and particles detach from the delicate web surface and disperse throughout the production area. Within minutes, a thin haze of tissue dust can settle on equipment, sensors, and control panels.

Why Tissue Converting Generates So Much Dust

Tissue paper is one of the most challenging materials to process. Its low basis weight and open fiber structure make it prone to mechanical fiber release during nearly every converting step. As the web runs through high-speed lines — often exceeding 500 m/min — airflows detach surface fibers, while embossing, perforation, and slitting create additional dust and fluff.

Modern production trends intensify the problem. Premium softness, reduced basis weights, and eco-friendly fiber blends all weaken fiber bonding strength, leading to higher dust levels. Meanwhile, faster machine speeds and larger embossing patterns increase mechanical stress on the web. The result: high airborne dust concentrations, contaminated machinery, and deteriorating working conditions.

Impact of Uncontrolled Dust

Dust particles can reattach to the tissue surface, causing lint, uneven embossing, or visible defects — particularly unacceptable in premium facial or toilet tissue. Accumulated dust also clogs sensors and drive components, resulting in frequent cleaning stops, shorter production runs, and increased maintenance costs. In severe cases, it can even pose a fire or explosion hazard near heated machine parts.

For operators, continuous exposure to fine fiber dust creates respiratory and safety concerns. In many converting plants, fine dust settles on every surface within hours, compromising both hygiene and occupational safety.

Conventional exhaust systems are not sufficient enough

Conventional exhaust systems or overhead hoods capture only part of the airborne dust and fail to prevent re-deposition on the web. In contrast, in-line web cleaning systems act directly at the source, removing particles from the web before they can spread. This not only improves product quality but also keeps the entire production area cleaner.

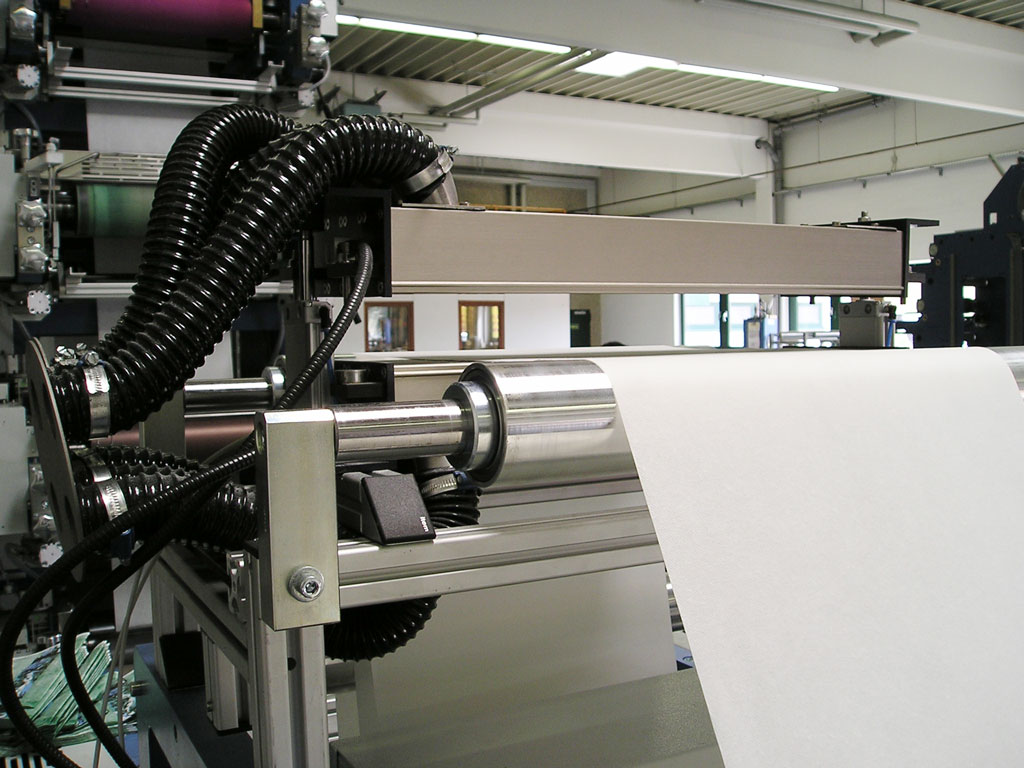

KELVA’s non-contact web cleaning technology is designed specifically for fibrous and delicate materials such as tissue. By breaking the boundary air layer that moves with the web, the system dislodges and extracts particles using a controlled combination of pressurized air and vacuum, while integrated antistatic equipment neutralizes surface charge to prevent re-attraction. Because it operates without physical contact, it treats even the thinnest tissue webs gently, without risk of mechanical damage. Another advantage of KELVA’s solutions is that they are relatively easy to retrofit into existing production lines thanks to their compact design and flexible configuration.

Case in Focus: Proven Performance in the Middle East

A major tissue manufacturer in the Middle East faced severe dust accumulation during the production of maxi rolls, facial tissue, and toilet tissue. To solve the issue, KELVA installed a TLX non-contact web cleaning system directly after the embossing station — the point of maximum dust release. The setup included a 2800 mm TLX cleaner head and an AFF-K42 filter unit with an integrated frequency converter to optimize airflow across different product formats. After installation, KELVA engineers conducted multiple trial runs to fine-tune airspeed and optimize suction parameters for the specific materials and line speeds of up to 500 m/min.

The results were clear. Substantial dust collection in the filter unit demonstrated the system’s high efficiency. The cleaner performed consistently across all product types, and the machine environment became noticeably cleaner, improving working conditions. The customer expressed full satisfaction and expects a return on investment within a year.

These findings are consistent with data from numerous KELVA installations worldwide, showing measurable and repeatable benefits across various converting processes. Typically, KELVA web cleaning systems achieve up to 80–90 % reduction in dust and airborne particles, increase productivity by up to 40 % through longer uninterrupted runs, and lower maintenance and spare part requirements. Waste and reject rates drop, operator safety improves, and most installations reach full payback within twelve months.

In short, the KELVA solution ensures a cleaner process, higher efficiency, and a safer workplace. This project highlights how a correctly positioned web cleaning system can effectively solve even the most demanding dust challenges — and underlines its growing importance in the rapidly developing Middle Eastern tissue market.

Looking Ahead: Dust Control as a Strategic Factor

As new production capacities emerge and manufacturers modernize their converting lines, the role of efficient web cleaning technology is more critical than ever. It is not merely a question of cleanliness but a strategic factor for consistent quality, operational reliability, and long-term profitability.

By removing dust at its source, KELVA’s web cleaning systems safeguard product quality, ensure cleaner working conditions, and boost overall efficiency — making dust control a key enabler of sustainable, high-performance tissue production.

contact

Our experts will be happy to help you. Get in touch with us!