KELVA Web and Sheet Cleaning Technology.

Wherever moving webs and sheets are involved, and debris can affect your production, we guarantee cleaner, safer, faster and more reliable production without reducing your output rate, thus increasing your production efficiency and lowering your costs.

By implementing KELVA web cleaning solutions, you lay an important foundation for occupational safety, health protection in your production as well as environmental safety.

KELVA is the inventor of industrial web cleaning.

We are manufacturing web cleaning equipment and have more than 50 years experience with industrial dust removal in reel-to-reel and sheet-fed production processes. Our specific systems for corrugated board, tissue, non-woven, film, glass, glass fiber, printing and other finishing assure you of the best web cleaning solution for your application.

Over 7.000 installations worldwide show that KELVA is a proven partner for dust and contamination free production. We develop profitable and customizable web cleaning and dust removing systems for any material and dust load. All of our equipments can be easily integrated or retrofitted.

KELVA’s promise to you: Your production will be cleaner, safer, faster and more reliable through implementing dust eliminating systems from KELVA. Through web cleaning you won’t loose any production speed, but you will increase your production efficiency and lower your maintenance costs.

Contact usUpcoming Events

explore the world of web cleaning

What is web cleaning, and why is it so important

Web cleaning is a crucial technology employed across various industrial processes such as printing, coating, laminating, and converting to ensure the quality and cleanliness of continuous rolls or webs of materials. This procedure involves the removal of contaminants and unwanted substances that can compromise the final product’s quality.

Learn moreAPPLICATIONS

Tailored to your needs

Our web cleaning solutions are individually adapted to a wide variety of applications. Thanks to our experience from over 7,000 installations, we find an efficient solution for all requirements

Learn moreMaterials

We clean them all

Whichever running web material you handle, there is hardly any substrate surface that cannot be quickly and efficiently freed from contamination.

Learn moreNON-CONTACT CLEANING

Clean with air

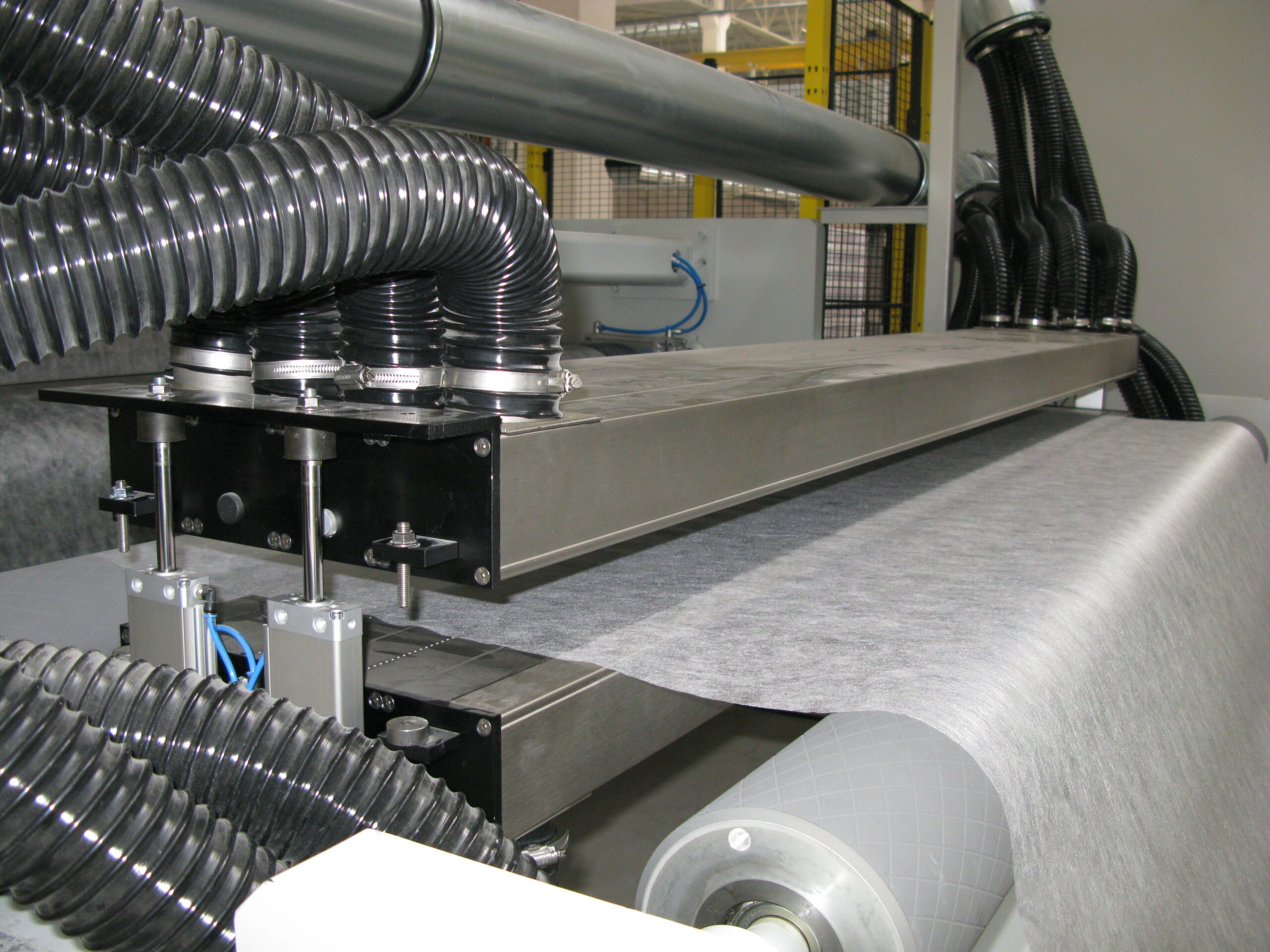

Non-contact cleaning is the ideal web cleaning method method for relatively high dust loads and sensitive webs where no contact with the material is allowed.

Learn moreContact CLEANING

Compact and efficient

Contact cleaning is well suited for applications with high demand on cleaning efficiency and lower dust loads.

Learn morecontact

Our experts will be happy to help you. Get in touch with us!