In plastics, film and foil production and converting, especially for food, medical or technical packaging applications, there is no way around web cleaning, even if cleanroom conditions already prevail in production.

Why 100% dust-removal in converting is crucial

As soon as plastic material web surfaces get exposed, after unwinding for example, they can be contaminated due to static charge or by environmental particles in the air, e.g. when paper, cardboard or other materials with high dust load potential were processed in the same location.

Dust and debris particles, even those seemingly insignificant, can settle on the material, leading to jeopardized product quality during converting and finishing. Serious non-compliance with legal standards, resulting in product recalls and damage to the company’s reputation as well as high costs and losses are the consequences.

Web cleaning will guarantee safe operation and provide healthy working conditions. Production efficiency will improve through significantly decreasing downtimes, maintenance costs and product rejects.

Choose the right web cleaning technology

Plastics, film and foil material can be cleaned excellently with both – contact or non-contact web cleaning.

To solve dust problems in narrow and mid web production of those, contact cleaning mostly fulfills the high cleaning performance requirements on one or both sides of the material.

However, the decisive factor is the web speed at which the production machine is running. For contact web cleaning, the limit is up to max. 400 m/min.

For speeds higher than 400 m/min, the KELVA non-contact web cleaning systems are the right choice. They are ideal for large web widths up to 10000mm and high web running speeds.

KELVA NON-CONTACT CLEANING

Due to no contact with the web, there is no damage on the web since the material remains untouched. There is no interference on web guiding or web tension. The compact and industrial design enables integration into practically any application and R2R-production environment. The maintenance costs are low and very few consumables are needed.

A non-contact web cleaning system from KELVA consists of a non-contact cleaner head with passive or active antistatic discharger, a filter/fan unit incl. optional control unit and a control unit as well as a connecting duct kit.

(Spain)

(Belgium)

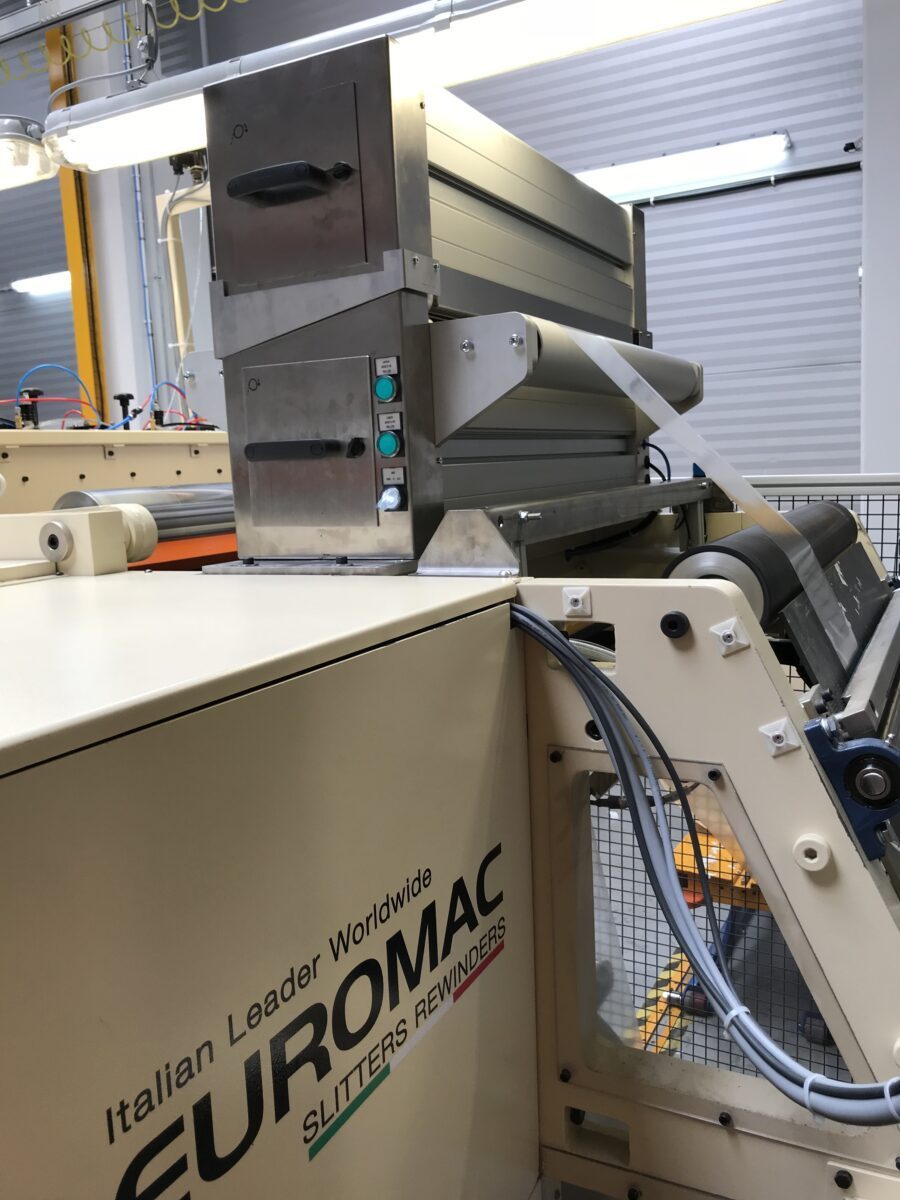

KELVA CONTACT CLEANING

The KELVA contact cleaners contain a special polymer roller for close contact to the web picking up almost 100% of all particles from the web passing through the cleaner even at low pressure.

The particles get transferred to a sheeted adhesive roller from which the sheets easily can be teared off when required. A static discharger at the outlet ensures, that the web does not re-attract dust.

Looking for a web cleaning solution to improve your production and save costs?

Feel free to give us more details about your Application, Material, Dust type(s), Web width (mm) and Web speed (m/min), so that we then can already take your information into account when contacting you.

Our experts will be happy to help you. Contact us!