For printing on paper, solid board, corrugated board, films and foils etc., the material surfaces must be dust-free. If there is any dust or other debris on a surface to be printed, the ink will not be applied evenly, dirt particles will settle on the ink rollers and disturb the transfer image.

In digital printing, clean print surfaces are extremely important because the printing systems are equipped with very sensitive print heads. They are much more delicate, that the ink rollers in a traditional offset printing machine. Dust on the print material surface clogs the print nozzles and quickly damages the digital print heads, which leads to poor print results (e.g. streaking effects), so that the print heads have to be replaced much more often. This causes maintenance costs and often unproductive downtime. Integrated web cleaning avoids this, including misproduction and associated waste.

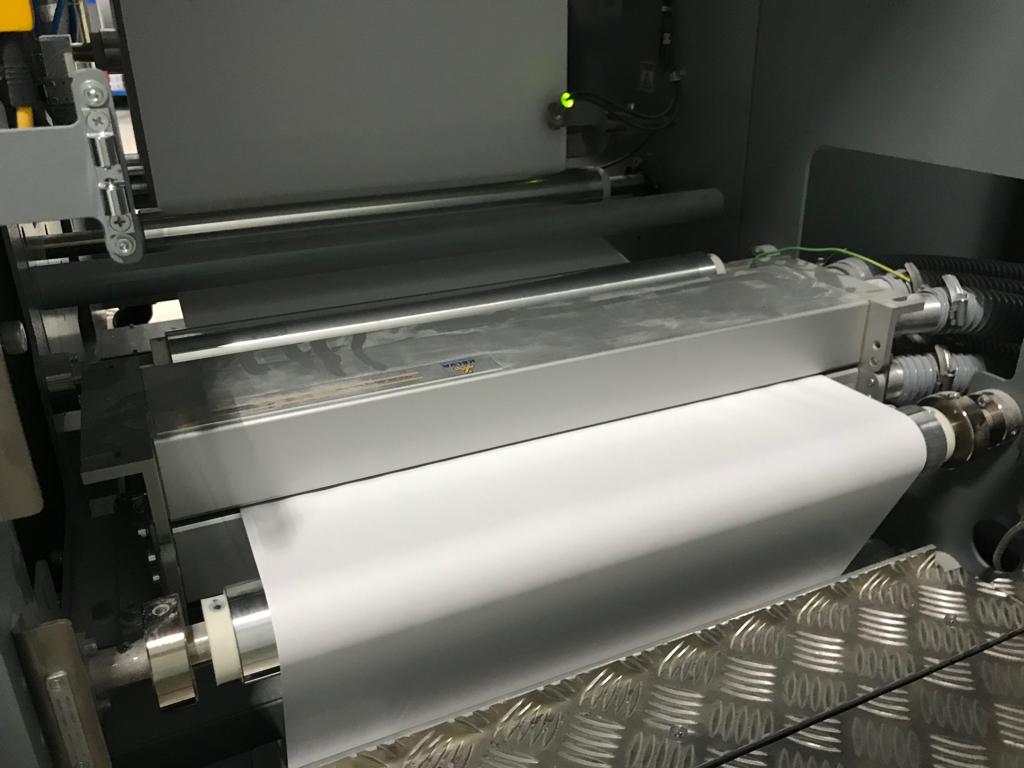

Kelvas web cleaning systems for printing combine full-speed production with full-width cleaning. This ensures continuous production with a measurable reduction of dust and debris, resulting in high-quality printed products and massively reduced downtimes, maintenance and spare parts costs.

Printing industry

Looking for a web cleaning solution to improve your production and save costs?

Feel free to give us more details about your Application, Material, Dust type(s), Web width (mm) and Web speed (m/min), so that we then can already take your information into account when contacting you.

Our experts will be happy to help you. Contact us!